Huntkey Central Lab, built in 2001, covers 2,000 square meters and focuses on the areas of new materials, experimental technique application and product function testing. It is an integrated lab base center that includes Acoustics Lab, EMC Lab, Function Lab, HALT Lab, Material Lab, Optical Lab, Reliability Lab, Safety Lab and Simulation Lab.

Acoustics Lab can carry out electro-acoustic index test for electronic fan and AV products, including sound pressure testing, sound power testing and wind tunnel testing.

EMC Lab has established an independent and comprehensive test system, which has a standard 3m semi-anechoic chamber, conduction shielded chamber, harmonic/scintillation lab, ESD lab, EFT lab, surge lab, etc.

Function Lab fulfills inrush current test, input current test, efficiency test, standby power test, loop stability test, component stress, dynamic load test, cross-load test and voltage dips test.

HALT Lab is equipped with ATS, nitrogen tower, accelerated heat box, accelerometer, etc. Product defects and weaknesses can be detected quickly in this lab.

Material Lab conducts experimental testing for reliability and electrical property validation of raw materials and electronic components. It also undertakes failure analysis of product life cycle.

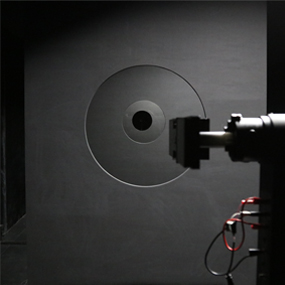

Optical Lab is equipped with integrating sphere and optical chamber, taking tests to the color parameters, luminosity parameters and electrical parameters of lighting products.

Reliability Lab can conduct vibration test, shock test, temperature and humidity test, MTBF test, salt mist test, etc.

Safety Lab carries out inspecting and testing at seven hazards in safety standard: electric shock, fire hazard, energy-related hazard, heat-related hazard, mechanical hazard, radiation and chemical hazard.

Simulation Lab includes thermal simulation, mathematic simulation, circuit simulation, PCB design simulation, etc.